Recently (24 July 2020), we had a signing Memorandum of Understanding (MOU) for lean six sigma (Yellow Belt Certification) ceremony between Lenoxcells Sdn Bhd and SEGi College Penang. This MOU commits both parties to work together more closely towards the common goal, which is the pursuit of the quality of engineering programs and students employability. Each side will pursue many significant activities, such as the promotion of lean six sigma certification in students study that enhances the students’ knowledge and skills to meet industry requirement.

The reason for introducing additional add-value skills of lean six sigma yellow belt certification is to enable the students to acquire relevant knowledge and skills in align with industry requirement. With the intense competition from peers, the topic in engineering has become essential to the engineering profession to be more competitive for such exposure to advance to the next level. Therefore, this topic package of lean six sigma, which becomes an additional asset to existing education certification is designed to provide insight and additional knowledge to students who wish to explore the field of the engineering profession.

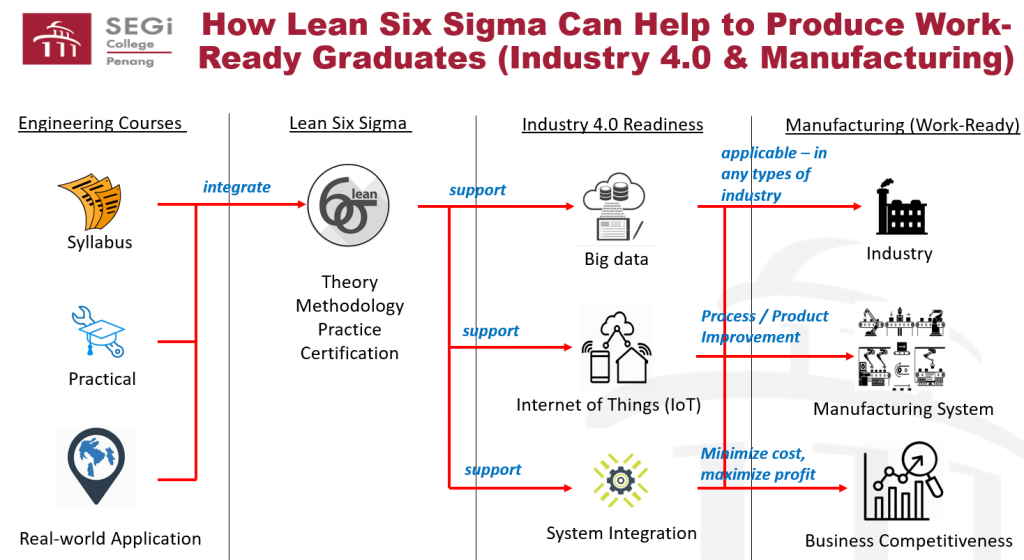

The introduction of lean six sigma as an additional course in Engineering field pertains the students to improve the quality of matter learning, building versatile in character and also the quality of study and college life from education perspective point of view. When the lean six sigma is embedded in the engineering courses, it teaches the students the process and strategy to eliminate errors within processes and meet customer satisfaction and cost reduction by leading the revenue growth and productivity improvement in an organization. The add on the value of this course leads the students to enhance their analytic and process skills to solve problems in industries.

In addition, students will expose to the concept of lean six sigma that supports 3 pillars of Industry 4.0 which are big data, internet of things (IoT) and system integration. With this additional knowledge, the students are readily equipped with transferable skill within or across the domain of engineering, big data, internet of things (IoT), system integration and lean six sigma where students can apply in any industry such as process or product improvement in manufacturing system and minimize cost or maximize profit in increase the organization business competitiveness in the market. In short, lean six sigma induces a change of attitude in students character, improve students ability to be the functionality of the organization that helps the students to be work-ready in the industry besides having traditional education certification.

Keyword:

Lean six sigma, yellow belt certification, engineering, SEGi College Penang, Industry 4.0, big data, internet of thing, system integration, work-ready graduates, school of engineering, mechanical engineering, electronics and electrical engineering, industry, manufacturing