By Nurul Natasya Binti Md Drus, Lecturer, School of Allied Health Sciences

Nowadays, 5S practice has been adopted by many organizations to organize the workplace towards reducing waste and improving productivity. Moreover, this practice also promotes a safer and more efficient environment in organizations. 5S practice is often viewed as an effective method for increasing efficiency and productivity. By reducing clutter, 5S helps in creating a safer and healthier workplace. This systematic process of housekeeping has been implemented not only in major industries in Japan, but it has also been widely adopted in retail shops and even in their houses.

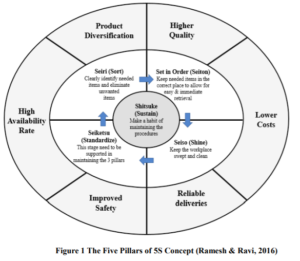

Besides that, safety, on the other hand, is an integral part of the first three “S” in the 5S practice: Sort, Set in Order, and Shine. The remaining two “S” – Standardize and Sustain – are the methods used in ensuring that safety and good housekeeping are maintained. Figure. 1 below shows the five pillars of the 5S concept with improved safety as one of its main advantages besides product diversification, higher quality, lower costs, reliable deliveries and high availability rate.

A good workplace can help in preventing defects and in preventing accidents from happening. Besides, Harea et al. (2018) had concluded that the 5S method can increase an organizations’ productivity and promote a safer workplace. Randhawa and Ahuja (2017) had conducted a research to evaluate the contribution of 5S implementation in Indian manufacturing industries. The findings had shown that the implementation of 5S had benefited the organizations in terms of productivity, quality, safety, employee morale values, effective workspace utilization and cost optimization.

The advantages provided by the 5S practice are also in line with the Occupational Safety and Health Master Plan for Malaysia 2016-2020’s (OSHMP 2020, 2016) main strategy which is to establish a preventive culture in the workplace. This strategy has been developed to transform the workplace in Malaysia into a safe and healthy environment in protecting workers as the most important asset. The 5S Audit has a very strong positive correlation with safety management performance and it is an effective tool in identifying opportunities for improvement which can help the organizations in analysing their strengths and weaknesses. It has been categorized as a crucial tool in ensuring an accurate deployment of 5S in any organization (Ho, 1999b).

A research study conducted by Ghodrati and Zulkifli (2012) had concluded that training is the key to the success of 5S. Without proper training, there will be a lack of capable workers, thereby making it impossible to implement 5S. 5S training has been identified as having a strong positive correlation with safety management performance. 5S training teaches the basic principles of 5S to employees. Such training also assists them in getting a clear understanding of the importance of an effective working environment. A conducive workplace can definitely create a safer and healthier work environment with lower risk activities.

Top management commitment is another crucial criterion in the implementation of 5S. The commitment of top-level leaders has always been considered as the biggest contributing factor to their success. Leadership is placed at the centre in a process-based quality management system model for ISO 9000:2015 standard. It shows that the commitment of top management is crucial for any type of improvement effort. To achieve long term success in safety performance, leadership engagement with senior managers is crucial (Shang et al., 2011). Other than that, employee involvement has a medium positive correlation with safety management performance. Like top management commitment, employee involvement has also been considered as one of the biggest success factors for any type of improvement effort. If the leaders can successfully encourage and motivate the staff in working towards achieving the 5S objectives, the staff will also work hard to improve the performance of safety management.

As a conclusion, 5S has been proven as an effective method in creating a conducive workplace, thereby improving its efficiency, effectiveness, productivity and safety. Improving the safety and health of the workers is usually not the main aim of 5S implementation in most organizations. However, various studies conducted on 5S implementation have shown a positive relationship between 5S practice and safety management performances.